Order Placing&Customized Production

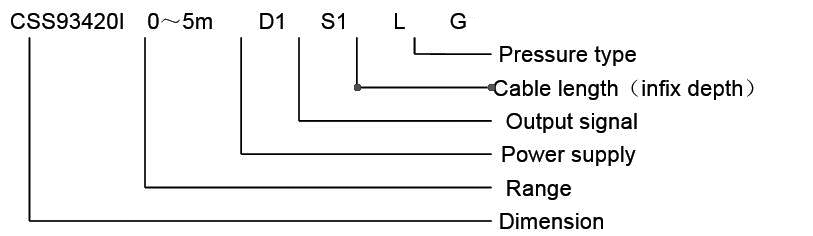

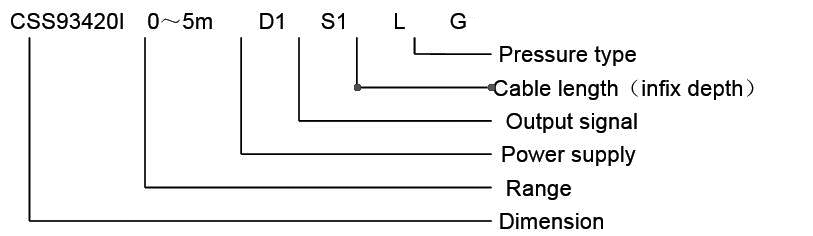

Ordering example:

Ordering information

Ordering information

| CSS93420 |

submersible transmitter |

| |

Code |

Dimension |

| I |

Blue terminal box |

| II |

Blue 2088 housing(without display) |

| III |

Blue 2088 housing ,LED display |

| IB |

Full weld |

| |

Range |

0~1...200m |

| (0-X)m |

X: Range |

| |

Code |

Power supply |

| D1 |

24VDC |

| D2 |

Others |

| |

Code |

Output signal |

| |

S1 |

4~20mADC |

| S2 |

1~5VDC |

| S3 |

0~5VDC |

| S4 |

0~10mAC |

| S5 |

0~20mAC |

| S6 |

0~10VDC |

| Code |

Cable length/Infix depth/length of flexible pipe |

| L |

Actual length |

| |

Code |

Pressure type |

| G |

Gauge pressure |

| A |

Absolute pressure |

| S |

Sealed gauge pressure |

Ordering note:

- Media must compatible with wetted parts.

- There is two kinds of cable can be choose, one is common with gas tube, another is diesel oil &gasoline proof.

- If the transmitter need LCD or LED display that the power supply should no lower than 20VDC。

- To ensure the products can working reliable, we suggest that customer install lightning protection device and make sure products & power are earthed.

- If the range is lower than 0.5m,the accuracy would be ±1%

- Special requirement, such as strong shock, moment vibration, strong electromagnetism, radio frequency interference , please consult us.

Warranty:

Pressure transmitters have a limited one-year warranty to the original purchaser. Smart Sensor will replace or repair defective products free of charge. This warranty does not apply to any units have been modified, misused, neglected .

On-site installation example

►The wire is a special waterproof wire. It should be free from wear, puncture and scratches during installation and use. If the above problems exist on the site, the conductor should be protected.

►If you encounter problems during installation and use, please contact our company. When the product is abnormal,please do not open it for repair by yourself.