The single-loop intelligent measurement and control instruments using dedicated integrated chip, measuring input and output with digital correction and self-calibration techniques, so the measurement is accurate and stable by eliminating the effects of temperature drift and time drift error. The instrument adopted a multi-protection and isolation optimization design, achieved the purpose of stronger anti-interference ability, higher reliability.

The single-loop intelligent measurement and control instrument’s hardware was greatly reduced, its composition is relatively simple,compatible with a variety of input signals (thermocouple / RTD / linear voltage / linear current / linear resistance, etc.).

By conjunction with variety of sensors, or transmitters, it can realize the measuring and control of temperature, pressure, level, length, capacity,force and other physical measurement, display and alarm control, so its application is very wide.

Technical Parameters:

1, Display: single row measuring value LED display, monochromatic beam simulation shows the percentage of the measured value

2, Display range: -1999 ~ 9999

3, Measurement accuracy: ± 0.5% FS ± 1d or ± 0.2% FS ± 1d

4, Input signal:

◆Thermocouple: K, E, S, B, J, T, R, N, etc., cold-side temperature automatic compensation

◆Thermal resistance: Pt100, Cu50, etc., the lead resistance should be less than 10Ω

◆DC voltage: mV, 0 ~ 5V, 1 ~ 5V, 0 ~ 10V (external resistor divider) and so on

◆DC current: 0 ~ 10mA, 0 ~ 20mA, 4 ~ 20mA and so on

◆Linear resistance: 0 ~ 400Ω (remote pressure gauge)

5, Alarm function: ultimate upper limit, upper limit, ultimate lower limit, lower limit .

6, Transmission output accuracy: ± 0.3% FS, load capacity: 500Ω

7, Relay contact capacity: AC240V / 3A @ DC24V / 3A (no inductive load)

8, Instrument working voltage: 220V ± 10V, power consumption ≤ 5W

9, Instrument size: hole 152 * 76mm, shape 160 * 80 * 90mm

10, Working environment: temperature 0 ~ 50 ℃, relative humidity <85%, no corrosion and vibration occasions.

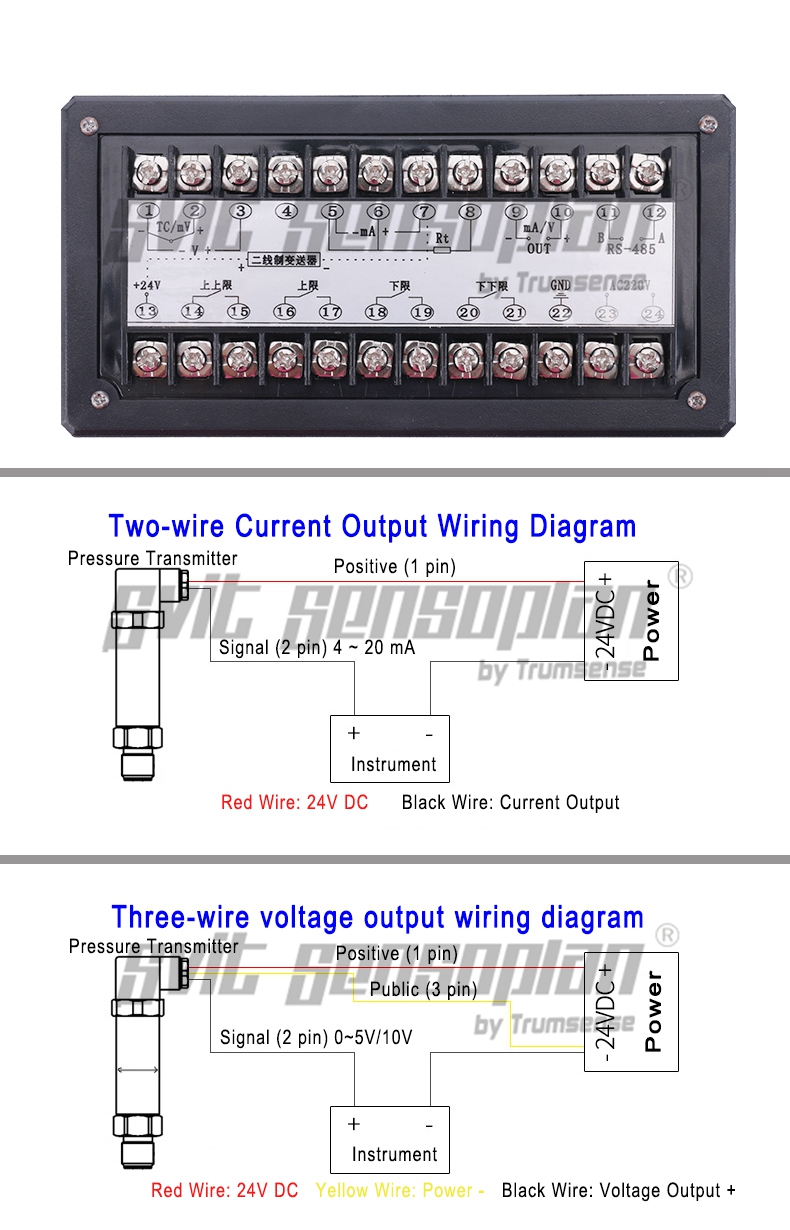

Wiring: Instrument Panel:

Instrument Panel:

Displaying instructions

A, Digital display:

Display the measured value in running state;

The setting code or parameter value is displayed in the setting status

B, Light bar display:

Visual display of the ratio of the measured value

C, Indicator:

AHH red light is the ultimate upper limit alarm indicator

AH red light is the upper limit alarm indicator

A green light is the lower alarm indicator

ALL green light is the ultimate lower limit alarm indicator

Panel Key Instruction: Typical Wiring Diagram For Liquid Level Transmitter:

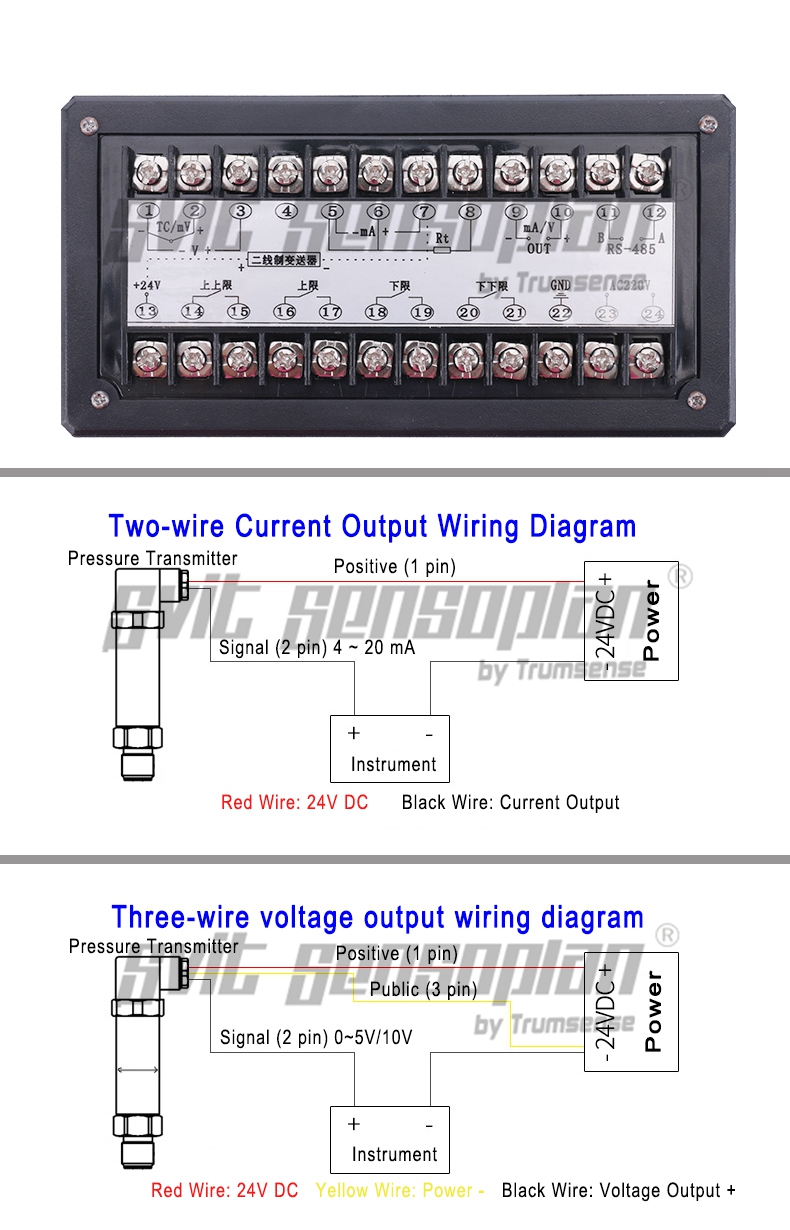

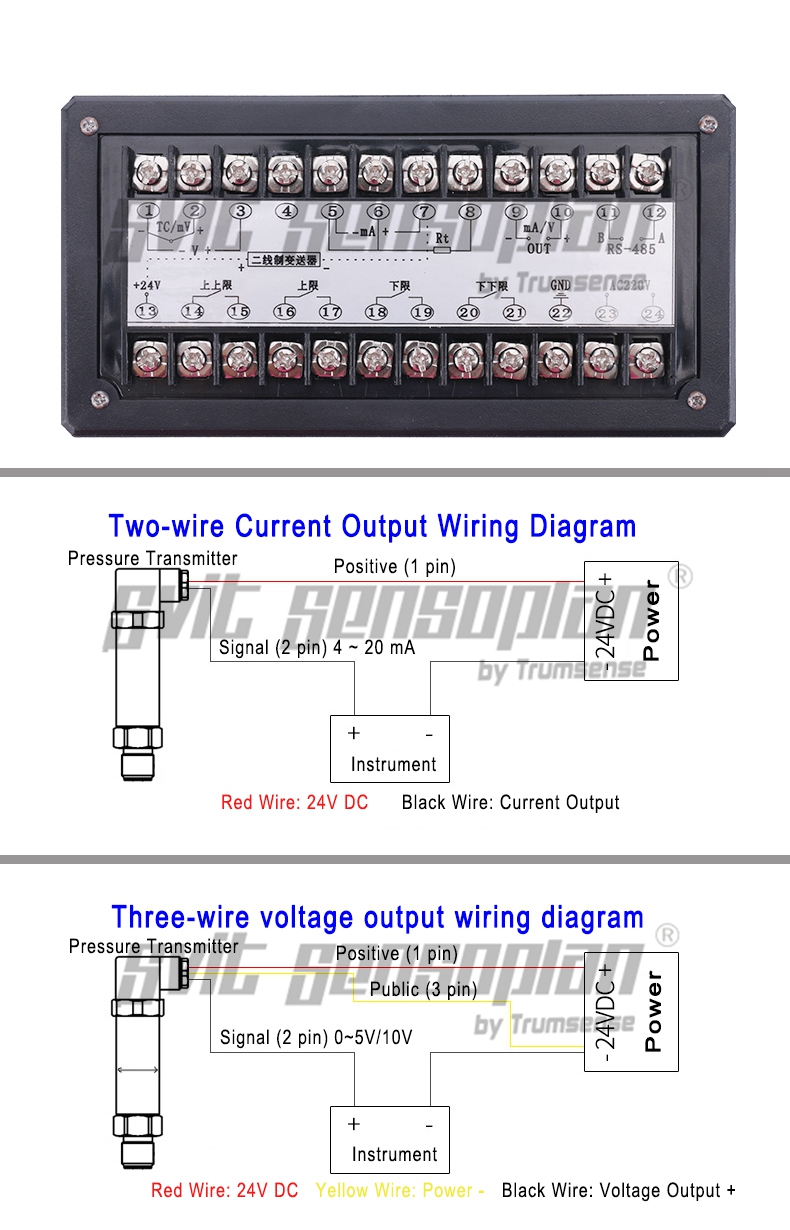

Typical Wiring Diagram For Liquid Level Transmitter: Typical Wiring Diagram For Pressure Transmitter:

Typical Wiring Diagram For Pressure Transmitter: Recent Order Photo Show for This Single Column Liquid Level Display Instrument:

Recent Order Photo Show for This Single Column Liquid Level Display Instrument:

We are factory, and will always satisfy with your specific application:

★ Other output are available: (contact us for offer online if you are in need of them)

4 wires relay output

2 wires relay output + Transmitting output

4 wires relay output + Transmitting output

2 wires relay output + RS485

other output acceptable to produce for you.

★ Other horizontal or double column instruments are available, please contact us: